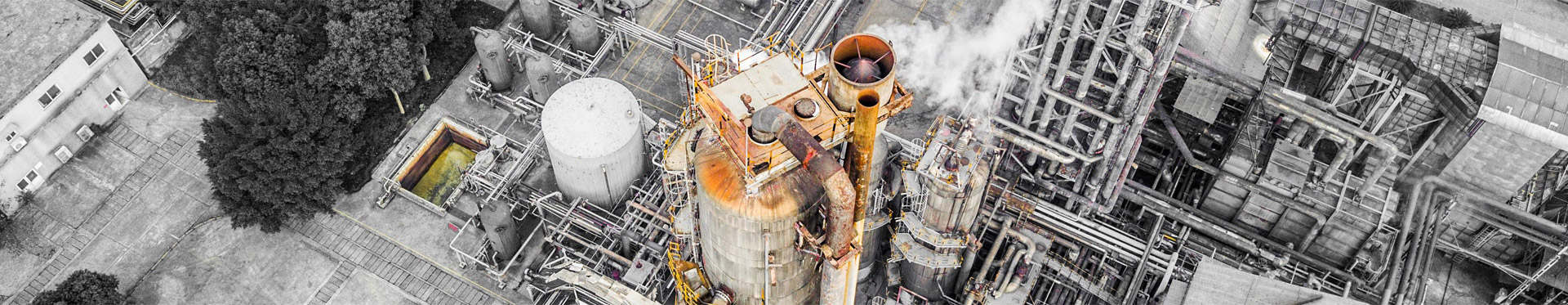

Songbei QA | How to maintain and repair explosion-proof lamps?

Date:2022-03-30 17:14:27 Views:1241

A: Explosion-proof lamps must be checked before installation: explosion-proof type, category, level, protection level of the shell; installation method and fastener requirements for installation, etc. The installation of explosion-proof lamps should be firmly fixed, the fastening bolts should not be replaced arbitrarily, and the spring washers should be complete. When installing the dustproof and waterproof sealing ring, place it as it is. At the cable entry, the cable and the sealing gasket should be closely matched, the section of the cable should be round, and the surface of the sheath should not have defects such as unevenness. The excess wire inlet must be blocked according to the explosion-proof type, and the compression nut must be tightened to seal the wire inlet.

Explosion-proof lamps and lampshades should be cut off before opening. A warning sign with the words "It is strictly forbidden to open with electricity" should be set up at the obvious place on the casing. The surface temperature of some light sources is relatively high, so pay attention to this when opening the cover quickly. Explosion-proof fluorescent lamps have an interlock mechanism to open the cover and cut off power, which provides convenience and safety guarantee for maintenance work. Because the fluorescent lamp is a cold light source lamp, there is no high temperature on the surface, and the cover can be opened immediately after the power is turned off.

When replacing the light source, the explosion-proof joint surface of explosion-proof lamps should be properly protected and not damaged; the cleaned explosion-proof surface should be coated with phosphating paste or 204-1 anti-rust oil, and other paints are strictly prohibited; no explosion-proof surface should be painted. There is a rust layer, if there is slight rust, there should be no pitting phenomenon after cleaning. The sealing ring used for dustproof and waterproof must be kept intact, which is very important for increased safety lamps. If the sealing ring is seriously damaged, replace it with a sealing ring of the same specification and material, and replace the entire lamp if necessary. When overhauling, pay attention to whether the lampshade is in good condition. If it is broken, replace it immediately.

Portable lamps are divided into two types: powered by the feeder network and self-contained power. For lamps powered by the feeder network, rubber sheathed cables should be used between explosion-proof junction boxes (boxes) or explosion-proof plug-in lamps, and their grounding or neutral cores should be in the same sheath; The minimum allowable cross-section is 25 square millimeters of YC and YCW heavy-duty rubber-sheathed cables. It is important to emphasize one point here: the cables of portable luminaires are not allowed to have intermediate connectors.

The explosion-proof explosion-proof lamp produced by Songbei Explosion-proof Electrical Appliances is made of aluminum alloy die-casting with high strength; the surface is high-voltage electrostatic spraying, which has strong corrosion resistance and light structure. Suitable for various installation methods.