1. It's made of copper or stainless steel material, Copper surface can be passivated or nickel plated,

2.It Convenient installation, wide application scope and high reliablity

3. Suitable for clamping and fastening various kinds of armored cables( DQM9 and DQMIL) or unarmored cables(DQM1I),

4. Ex-mark: Exe I is equal to Exe II 2G Exe II (European Standard) Degree of protection: IP65

Applcations

1.Hazardous: division 1&0

2.Explosive gas atmosphere: class I A, B, lC

3.Indoor or outdoor (P65)

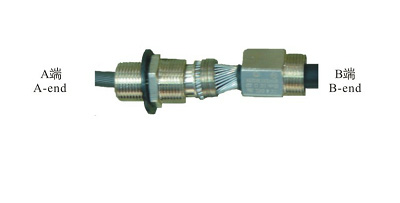

Installation diagram

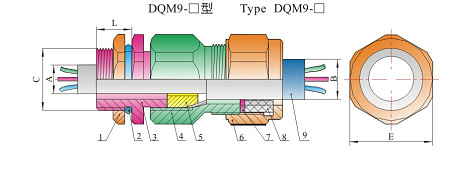

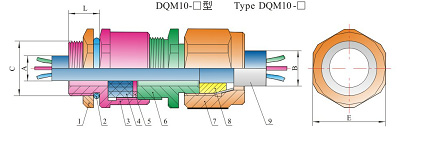

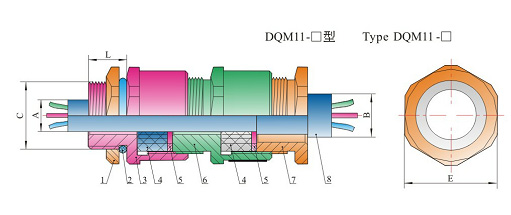

Outline dimensions

1. Nut 2.Sealing ring 3.Entry body 4.Middle body 5.Taper sleeve 6.Compression nut 7.Washer 8.Sealing ring 9.Armoured cable

|

(G) |

Metric |

Thread length |

Sealing range of cable dia |

Max thickness of Steel braid |

Diamet-er of steel wire |

Wire of Max.th-inknes-s braid |

Max.dia-meter E |

||

|

A (mm) |

B (mm) |

Min |

Max |

||||||

|

|

M16x1.5 |

12 |

6.5 |

6.0-10 |

0.1 |

0.4 |

0.9 |

0.85 |

24 |

|

G1/2” |

M20x1.5 |

12 |

8.6 |

6.0-13.4 |

0.1 |

0.4 |

0.85 |

0.85 |

24 |

|

G3/4” |

M25x1.5 |

12 |

11.6 |

9.5-15.9 |

0.1 |

0.4 |

0.9/1.25 |

0.85 |

30 |

|

G1” |

M32x1.5 |

16 |

19.9 |

19-25 |

0.1 |

0.7 |

1.25/1.6 |

1.25 |

43 |

|

G1 1/4” |

M40x1.5 |

16 |

26.2 |

24-30 |

0.1 |

0.7 |

1.6/2.0 |

1.40 |

50 |

|

G1 1/2” |

M50x1.5 |

16 |

32.1 |

26-35 |

0.1 |

0.8 |

1.6/2.0 |

1.40 |

60 |

|

G2” |

M63x1.5 |

17 |

38.1 |

35-46.7 |

0.2 |

0.63 |

2.0/2.5 |

1.40 |

65 |

|

G2 1/2” |

M75x1.5 |

17 |

50 |

45.6-59.4 |

0.2 |

0.63 |

2.5 |

1.50 |

80 |

|

G3” |

M100x1.5 |

19 |

61.9 |

57-72.1 |

0.3 |

0.81 |

2.5 |

1.50 |

92 |

|

G4” |

|

19 |

86 |

76-93 |

0.3 |

0.94 |

3.15 |

1.60 |

117 |

|

Metric |

(G”) |

Thre-ad Leng-th |

Sealing range of Cable dia. |

Max thinkness of steel braid |

Diame-ter of Steel wire |

Wire mak. Thinkn-ess of braid |

Max.dia-meter E |

||

|

A(mm) |

B(mm) |

Min |

Max |

||||||

|

M16x1.5 |

|

12 |

6.5 |

6.0-10 |

0.1 |

0.4 |

0.9 |

0.85 |

24 |

|

M20x1.5 |

G1/2” |

12 |

8.6 |

6.0-13.4 |

0.1 |

0.4 |

0.85 |

0.85 |

24 |

|

M25x1.5 |

G3/4” |

12 |

11.6 |

9.5-15.9 |

0.1 |

0.4 |

0.9/1.25 |

0.85 |

30 |

|

M32x1.5 |

G1 |

16 |

19.9 |

19-25 |

0.1 |

0.7 |

1.25/1.6 |

1.25 |

43 |

|

M40x1.5 |

G1 1/4” |

16 |

26.2 |

24-35 |

0.1 |

0.7 |

1.6/2.0 |

1.40 |

50 |

|

M50x1.5 |

G1 1/2” |

16 |

32.1 |

26-35 |

0.1 |

0.8 |

1.6/2.0 |

1.40 |

60 |

|

M63x1.5 |

G2” |

17 |

38.1 |

35-45 |

0.2 |

0.63 |

2.0/2.50 |

1.40 |

65 |

|

M75x1.5 |

G2 1/2” |

17 |

50 |

45.6-59.4 |

0.2 |

0.63 |

2.50 |

1.50 |

80 |

|

M100x1.5 |

G3” |

19 |

61.9 |

57-72.1 |

0.3 |

0.81 |

2.50 |

1.50 |

92 |

|

|

G4” |

19 |

86 |

76-93 |

0.3 |

0.94 |

3.15 |

1.60 |

117 |

|

Metric |

(G”) |

Thread length(mm) |

Sealing range of cable dia. |

Max.dia-met-er E (mm) |

|

|

Cable inner diameter A |

Cable outer diameter B |

||||

|

M16x1.5 |

|

12 |

6-8.6 |

6-10 |

24 |

|

M20x1.5 |

G1/2” |

12 |

8.6-11 |

8-12 |

24 |

|

M25x1.5 |

G3/4” |

12 |

10-13 |

10-14 |

30 |

|

M32x1.5 |

G1” |

16 |

17-19 |

15-20 |

43 |

|

M40x1.5 |

G1 1/4” |

16 |

18-20 |

19-22 |

50 |

|

M50x1.5 |

G1 1/2” |

16 |

20-22 |

22-25 |

60 |

|

M63x1.5 |

G2” |

17 |

27-33 |

27-36.4 |

65 |

|

M75x1.5 |

G2 1/2” |

17 |

34-40 |

37-45.2 |

80 |

|

M100x1.5 |

G3” |

19 |

47-50 |

47-55 |

92 |

|

|

G4” |

19 |

50-58 |

56-62 |

117 |

|

(G”) NPT” |

Metric |

Threa-d Lengt-h (mm) |

Sealing range of cable dia. |

Max thickness of steel braid |

Max.T-hinkne-ss of wire braid |

Steel wire diamet-er |

Max.dia-meter E |

||

|

A (mm) |

B (mm) |

Min |

Max |

||||||

|

G1/2” |

M20x1.5 |

12 |

8 |

8-12 |

0.1 |

0.4 |

0.85 |

0.9/1.25 |

24 |

|

G3/4” |

M20x1.5 |

12 |

12 |

10-14 |

0.1 |

0.4 |

0.90 |

0.9/1.25 |

30 |

|

G3/4” |

M25x1.5 |

16 |

13.9 |

15-20.9 |

0.1 |

0.7 |

1.40 |

1.25/1.60 |

43 |

|

G1” |

M32x1.5 |

16 |

19.9 |

19-25 |

0.1 |

0.7 |

1.40 |

12.5/1.60 |

43 |

|

G1 1/4” |

M40x1.5 |

16 |

26 |

24-30 |

0.1 |

0.7 |

1.40 |

1.60/2.0 |

50 |

|

G1 1/2” |

M50x1.5 |

16 |

32 |

31-35 |

0.1 |

0.8 |

1.40 |

1.60/2.0 |

60 |

|

G2” |

M50x1.5 |

17 |

38 |

36-45 |

0.2 |

0.63 |

1.40 |

2.0/2.50 |

65 |

|

G2 1/2” |

M63x1.5 |

17 |

50 |

48-56 |

0.2 |

0.63 |

1.50 |

2.50 |

80 |

|

G3” |

M75x1.5 |

19 |

61 |

60-70 |

0.3 |

0.81 |

1.50 |

2.50 |

92 |

|

G4” |

M100x1.5 |

19 |

80 |

76-93 |

0.3 |

0.94 |

1.60 |

3.15 |

117 |

Features

1. Accord with the model implications rules to select regularly, and Ex-mark should be added behind model implication. The template as following: code for product model implication+Ex-mark. For example, we need explosion-proof cable clamping sealed connector of stainless steel whose code is 9, and thread is 11/4". The model implication Is DQM9G114g+Exe II.”

2. If there are some special requirements, it should be pointed as ordering