Scope of application

It is widely used in the connection of inlet and outlet of explosion-proof electrical equipment in hazardous environment such as oil exploitation, refining, chemical industry and military industry;

Applicable to areas 1 and 2 of explosive gas environment;

Applicable to flammable dust environment in Zone 20, Zone 21, Zone 22;

Applicable to II A, II B, II C explosive gas environment.

Feature of product

It has the advantages of flame resistance, corrosion resistance, water resistance, aging resistance, good flexibility, firm structure and reliable operation.

Thread specifications can be customized according to user requirements, such as NPT, metric thread, etc.;

The length of the flexible pipe can be specially processed according to user requirements.

BHJ series explosion-proof union (II C, DIP)

Scope of application

It is widely used for connection between steel pipe wiring in dangerous environment such as oil exploitation, refining, chemical industry and military industry;

Applicable to areas 1 and 2 of explosive gas environment;

Applicable to flammable dust environment in Zone 20, Zone 21, Zone 22;

Applicable to Class II A, II B, II C explosive gas environments.

Feature of product

Made of high quality carbon steel, the operation can be made of stainless steel according to user requirements;

Thread specifications can be customized according to user requirements, such as NPT, metric thread, etc.

DQM series explosion-proof cable clamp sealing joint (II C, e, DIP)

Scope of application

It is widely used in the clamping and sealing of cables in dangerous environment such as oil exploitation, refining, chemical industry and military industry;

Applicable to areas 1 and 2 of explosive gas environment;

Applicable to flammable dust environment in Zone 20, Zone 21, Zone 22;

Applicable to II A, II B, II C explosive gas environment.

product description

Implementation criteria:

GB3836.1, GB3836.2, GB3836.3, GB12476-1

Explosion-proof mark: Exe II/DIP A20, Exd II C/DIP A20

|

Model specification |

Through pipe diameter(mm) |

Tube inner diameter(D) |

Joint thread(G”) |

lengthL(mm) |

Maximum diameter(A) |

Minimum bending radius(mm) |

||

|

Type I |

Type II |

Type I |

Type II |

|||||

|

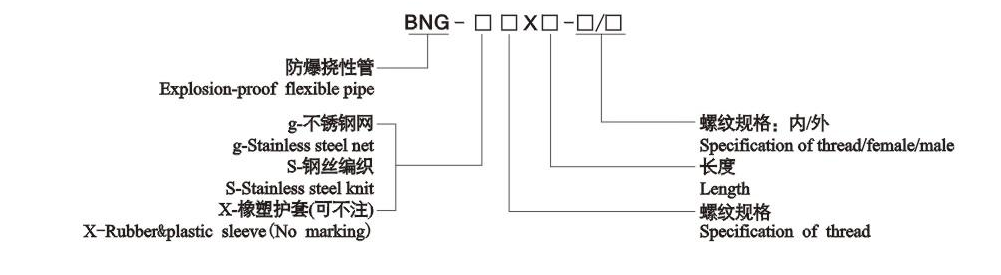

BNG口-700xG1/2 |

13 |

13 |

13 |

1/2 |

700 |

38 |

28 |

80 |

|

BNG口-1000xG1/2 |

13 |

13 |

13 |

1/2 |

1000 |

38 |

28 |

80 |

|

BNG口-700xG3/4 |

20 |

17 |

17 |

3/4 |

700 |

46 |

34 |

110 |

|

BNG口-1000xg3/4 |

20 |

17 |

17 |

3/4 |

1000 |

46 |

34 |

110 |

|

BNG口-700xG1 |

25 |

21 |

21 |

1 |

700 |

55 |

40 |

145 |

|

BNG口-1000xG1 |

25 |

21 |

21 |

1 |

1000 |

55 |

40 |

145 |

|

BNG口-700xG1 1/4 |

32 |

26 |

26 |

1 1/4 |

700 |

60 |

48 |

180 |

|

BNG口-1000xG1 1/4 |

32 |

26 |

26 |

1 1/4 |

1000 |

60 |

48 |

180 |

|

BNG口-700xG1 1/2 |

40 |

30 |

30 |

1 1/2 |

700 |

65 |

55 |

210 |

|

BNG口-1000xG1 1/2 |

40 |

30 |

30 |

1 1/2 |

1000 |

65 |

55 |

210 |

|

BNG口-700xG2 |

50 |

42 |

47 |

2 |

700 |

85 |

75 |

250 |

|

BNG口-1000xG2 |

50 |

42 |

47 |

2 |

1000 |

85 |

75 |

250 |

|

BNG口-700xG2 1/2 |

70 |

50 |

62 |

2 1/2 |

700 |

100 |

90 |

350 |

|

BNG口-1000xG2 1/2 |

70 |

50 |

62 |

2 1/2 |

1000 |

100 |

90 |

350 |

|

BNG口-700xG3 |

80 |

62 |

72 |

3 |

700 |

115 |

115 |

400 |

|

BNG口-1000xG3 |

80 |

62 |

72 |

3 |

1000 |

115 |

115 |

400 |

|

BNG口-700xG4 |

100 |

85 |

90 |

4 |

700 |

145 |

145 |

500 |

|

BNG口-1000xG4 |

100 |

85 |

90 |

4 |

1000 |

145 |

145 |

500 |