The explosion-proof lamp for flameproof, USES the seam allowance (threaded) flame-proof joint surface, shell USES high strength ca^t aluminum alloy, one-time die-casting molding, can withstand the pressure, the surface after the blast High pressure electrostatic powder coatings anticoiTosive performance is good, beautiful appearance. Equipped with coiTesponding power drive.

Inquiry

Product structure performance

The explosion-proof lamp for flameproof, USES the seam allowance (threaded) flame-proof joint surface, shell USES high strength ca^t aluminum alloy, one-time die-casting molding, can withstand the pressure, the surface after the blast High pressure electrostatic powder coatings anticoiTosive performance is good, beautiful appearance. Equipped with coiTesponding power drive. LED light source and light body for the rib structure, convenient installation, wiring and maintenance.

Each explosion-proof lamp shell joint adopts the n0n type sealing ring structure, protection performance is high, canreach IP65.This product has long life, energy saving, environmental protection, bright lights^ the advantages of light weight and beautiful appearance is an ideal practical explosion-proof lamps and lanterns.

Lamps and lanterns is exposed fasteners material adopt stainless steel, the anti-corrosion performance of lamps and lanterns is strong. Explosion-proof lamp can add emergency device, emergency lighting source, with LED light source, is suitable for the high places.

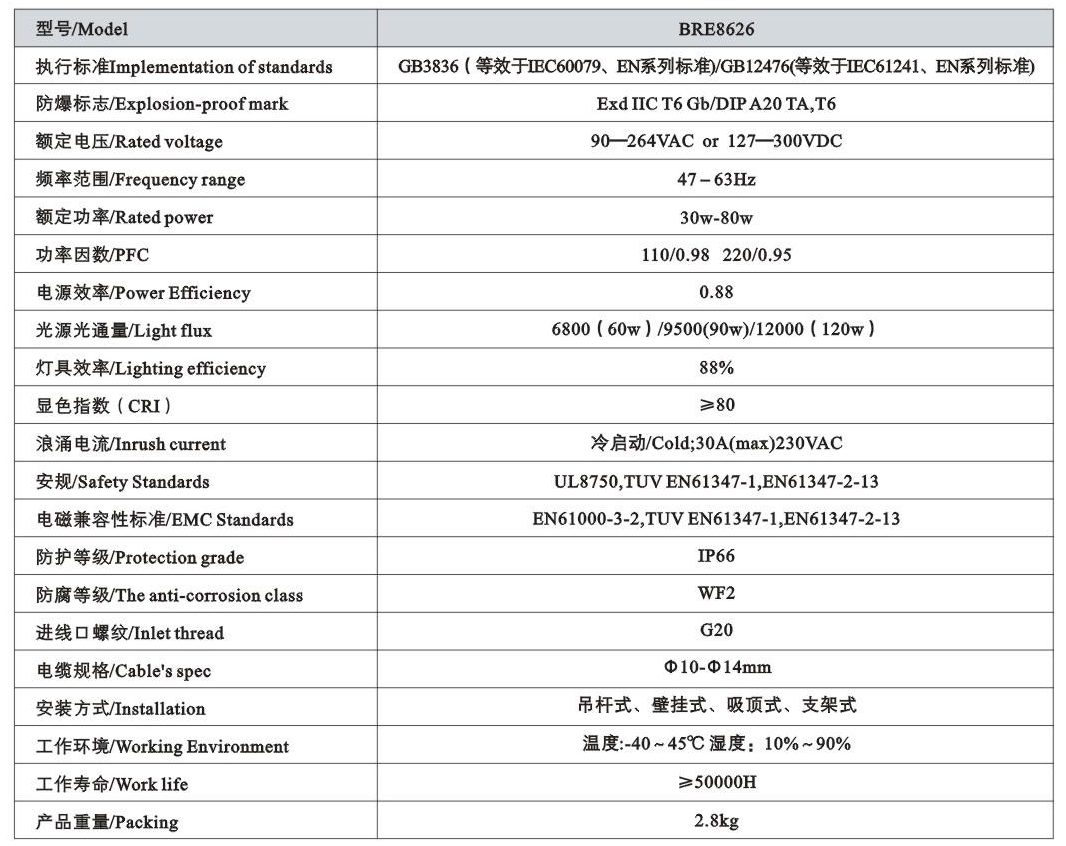

Model BRE8626

Implementation of standardsGB3836

Explosion-proof markExd nc T6 Gb/DEP A20 TA,T6

Rated voltage90—264VAC or 127—300VDC

Frequency range 47-63HZ

Rated power30w-80w

PFC110/0.98 220/0.95

Power Efficiency 0.88

Light flux6800 ( 60w ) /9500(90w)/12000 ( 120w )

Lighting efficiency 88%

Inrusli current Cold;30A(max)230VAC

Safety StandardsUL875 0,TUV EN61347-1 ,EN61347-2-13

EMC StandardsEN61000-3 -2,TUV EN61347-1 ,EN61347-2-13

Protection gradeIP66

The anti~corrosion class WF2

Inlet thread G20

Cable_s spec<D 10-014mm

Installation

Working Environment:10% 90%

Work life 50000H

Packing 2.8kg

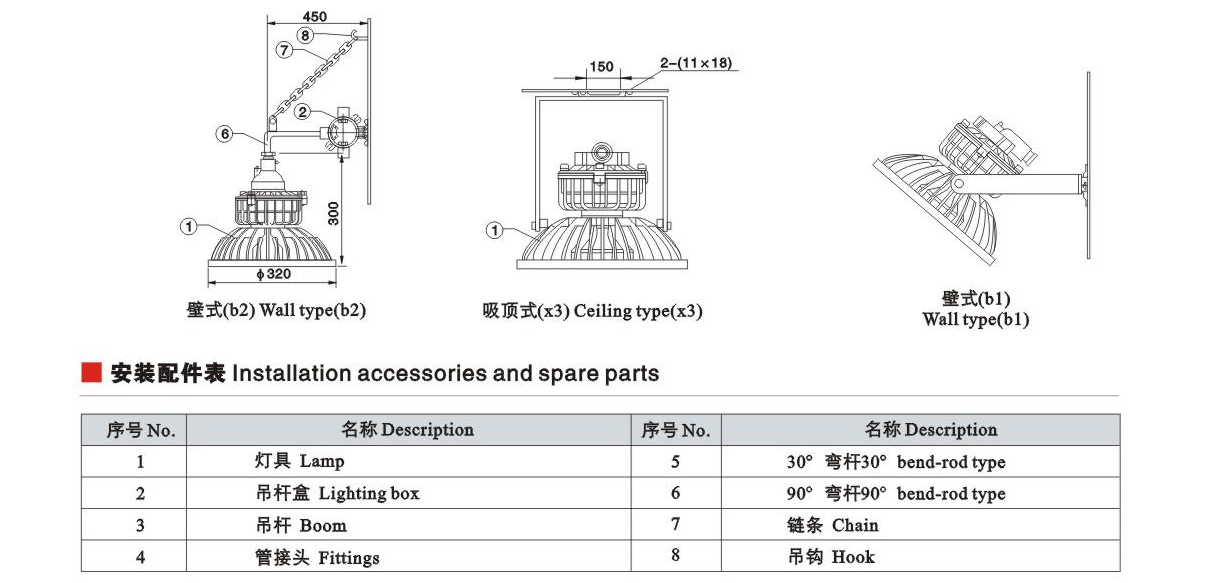

The explosion-proof lamp installation of steel pipe or cable wiring, which can be chosen by the customer.

Distribution curve

Order note

The use and maintenance

1.Explosion-proof lamp before use, first to check whether the content of the nameplate with customers ordering consistent;

2.Mixer explosion-proof lamp when installed into the first line cable by introducing device receivedby XianQiang terminals, and pressure sealing ring, cable seal is good, then good grounding line, fastening screws, the above after the check and correct, can use electricity;

3.Explosion'proof lamp shall not remove, maintenance, must be disconnected before level power supply after can open access; Oenerally do not need to repair this product has long life characteristics.

4.Pieces shall not damage the flame-proof surface in the process of maintenance, repair after tu rust-proof oil 204-1, good cover, tighten rear can use;

5.Explosion-proof lamp should be regularly check, clean up the dust on the surface of the transparent.

6.Mixer obstacles from the explosion-proof enclosure is greater than 30 mm.

Description

1.Lamp

2.Lighting box

3.Boom

4.Fittings

5.30° bend-rod type

6.90° bend-rod type

7.Chain

8.Hook

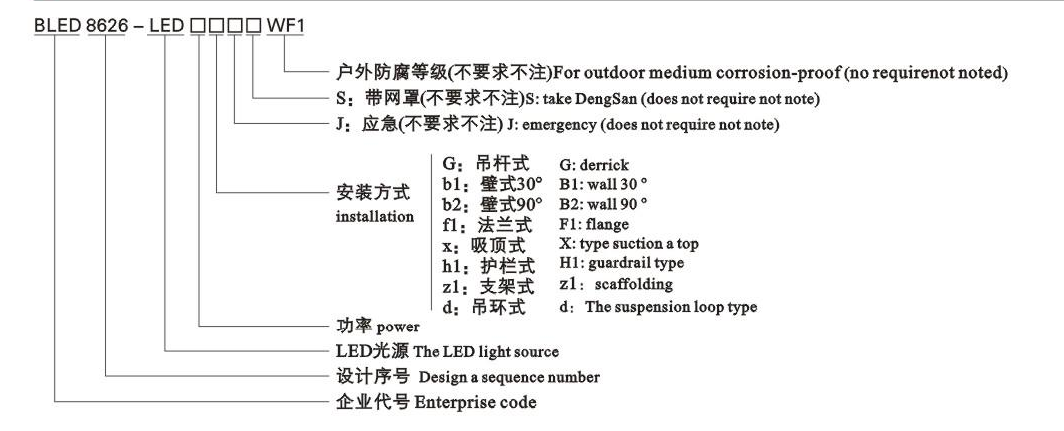

For outdoor medium corrosion-proof (No requ ire not noted)

S: belt the net cover(does not require not note)

J: emergency (does not require not note)

Main technical parameters