Scope of application

Applicable to areas 1 (indoor units) and 2 areas of explosive gas environment;

Applicable to II A, II B, II C explosive gas environment;

Applicable to the temperature group of T1~T4 group;

Adjust the temperature in workshops, control rooms, laboratories, etc. with temperature control requirements;

Widely used in oil exploration, oil refining, chemical, pharmaceutical, military and other hazardous environments and offshore oil platforms, oil tankers and other places.

*Please request Class II C, please specify;

Feature of product

Explosion-proof air-conditioning equipment is mainly used on the basis of domestic and foreign brands, using special process methods and manufacturing methods for explosion-proof

Processing to ensure that the air conditioner meets the requirements for explosion protection;

In general, in order to improve the safety performance of the product and the reliability of the user's on-site operation, the explosion-proof split wall-mounted air conditioner remote control

The device is directly fixed on the indoor control box, and the intrinsically safe power supply is used, and the battery is not required to be used, and the work is safe and reliable;

Explosion-proof split wall-mounted air conditioners are divided into functions according to functions: single cold type and cold and warm type;

The refrigeration and heating performance are stable, reliable and have a long service life;

LED or liquid crystal display for easy operation;

Compact structure and beautiful appearance.

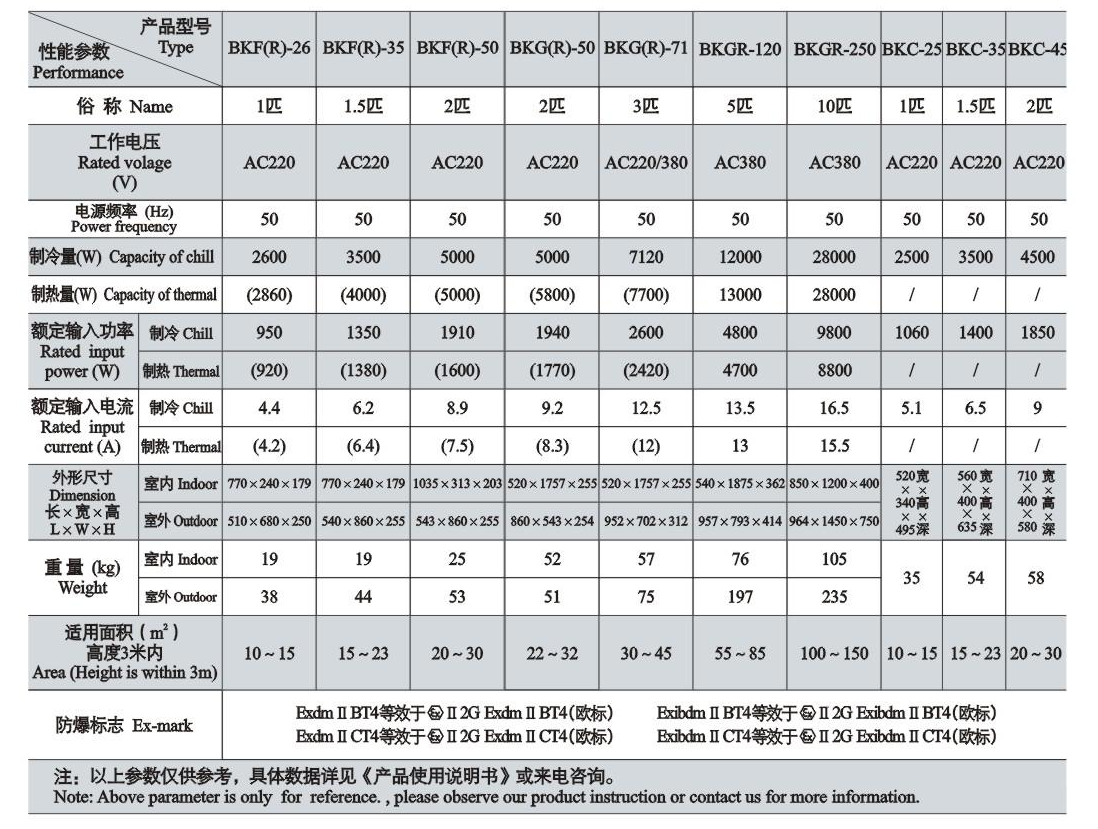

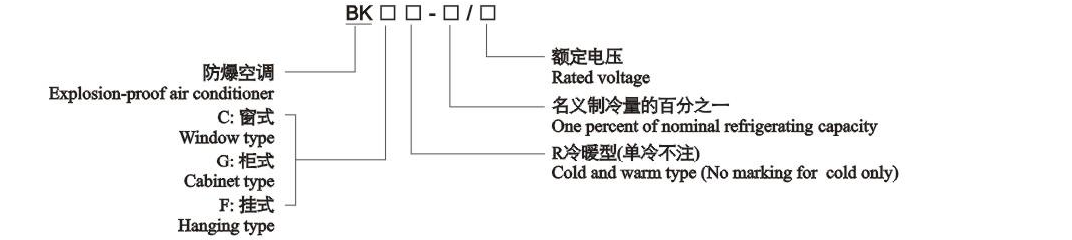

BK series explosion-proof split cabinet air conditioner (II B, II C)

Scope of application

Applicable to areas 1 (indoor units) and 2 areas of explosive gas environment;

Applicable to II A, II B, II C explosive gas environment;

Applicable to the temperature group of T1~T4 group;

Adjust the temperature in workshops, control rooms, laboratories, etc. with temperature control requirements;

Widely used in oil exploration, oil refining, chemical, pharmaceutical, military and other hazardous environments and offshore oil platforms, oil tankers and other places.

*Please request Class II C, please specify;

Feature of product

Explosion-proof air-conditioning equipment is mainly used on the basis of domestic and foreign brands, using special process methods and manufacturing methods for explosion-proof

Processing to ensure that the air conditioner meets the requirements for explosion protection;

In general, in order to improve the safety performance of the product and the reliability of the user's on-site operation, the explosion-proof split cabinet air conditioner is designed as

Manual control;

Explosion-proof split cabinet air conditioners are divided into functions according to functions: single cold type and cold and warm type;

Stable and reliable cooling and heating performance and long service life;

LED or liquid crystal display for easy operation;

Compact structure and beautiful appearance.

Selection table

Model specification

BK-25/220

BKR-25/220

BK-35/220

BKR-35/220

Cooling capacity (W)

2600

2600

3500

3500

Heating capacity (W)

/

2880

/

3900

Rated voltage /

frequency (V / Hz)

220/50

220/50

220/50

220/50

Input power (P number)

1P

1P

1.5P

1.5P

Cooling input power /

current (W / A)

742/3.3

742/3.3

1015/4.6

1015/4.6

Heating input power / current

(W / A)

/

798/3.6

/

1190/5.4

Applicable area (m2)

10-15

10-12

14-21

13-16

indoor

34.8/38.8

34.8/38.8

36.8/40.8

36.8/40.8

Noise

(dB)

outdoor

49

49

50

50

Indoor unit

265x790x170

265x790x170

275x845x180

275x845x180

Dimensions

(mm)

Outdoor unit

540x848x320

540x848x320

540x848x320

596x899x378

control box

300x500x190

300x500x190

300x500x190

300x500x190

Indoor unit

9

12

10

10

Weight

(kg)

Outdoor unit

37

44

38

41

control box

10

10

10

10

Connecting pipe length

(m)

3

3

3

3

|

|

BK-50/220 | BKR-50/22 | BK-71/220 | BKR-71/220 | |

| Cooling capacity (W) | 5000 | 5000 | 7260 | 7260 | |

| Heating capacity (W) | / | 5700 | / | 8100 | |

| Rated voltage / frequency (V / Hz) | 220/50 | 220/50 | 220/50 | 220/50 | |

| Input power (P number) | 2P | 2P | 3P | 3P | |

| Cooling input power / current (W / A) | 1432/6.5 | 1432/6.5 | 2200/10 | 2200/10 | |

| Heating input power / current (W / A) | / | 1690/7.6 | / | 2600/11.8 | |

| Applicable area (m2) | 24-36 | 22-27 | 29-48 | 27-34 | |

| indoor | 40/45 | 40/45 | 48 | 48 | |

| Noise (dB) | outdoor | 53 | 53 | 56 | 56 |

| Indoor unit | 325x1100x227 | 298x940x200 | 326x1178x253 | 326x1178x253 | |

| Dimensions (mm) | Outdoor unit | 655x860x330 | 700x955x396 | 790x980x440 | 790x980x440 |

| control box | 300x500x190 | 300x500x190 | 300x500x190 | 300x500x190 | |

| Indoor unit | 13 | 13 | 18 | 18 | |

| Weight (kg) | Outdoor unit | 52 | 54 | 65 | 68 |

| control box | 10 | 10 | 10 | 10 | |

| Connecting pipe length (m) | 4 | 4 | 4 | 4 | |