Oil & Gas News | Prospects for predictive maintenance tools in the oil and gas industry over the next 10 years

Date:2022-03-21 17:40:58 Views:1436

GlobalData said that over the next 10 years, predictive maintenance tools will be more widely used in critical infrastructure

in the oil and gas industry. The data analytics firm noted that predictive maintenance tools provide oil and gas companies

with operational and financial liquidity through the use of technology.

According to GlobalData's "Predictive Maintenance in the Oil and Gas Industry - Thematic Study" report, predictive

maintenance includes condition monitoring technology used to collect, store and analyze structural and operational

data of key equipment in the oil and gas industry. The analysis yields actionable insights into equipment health to

estimate equipment lifespan and help schedule maintenance and equipment replacement drills with minimal impact

on oil and gas operations.

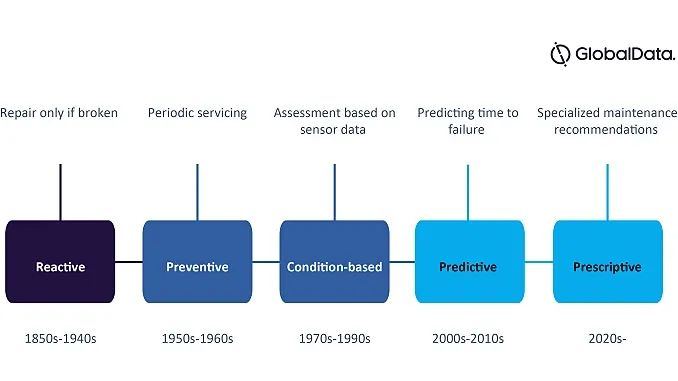

The evolution of maintenance strategies in the oil and gas industry (Source: GlobalData Oil and Gas Intelligence Center)

Maintenance strategies in the oil and gas industry have come a long way since the early 19th century. They have

evolved from a reactive approach to a preventive approach to ensure the supply chain operates continuously. These

strategies were developed in response to the economic emergency and technical support at the time and will continue

to do so in the future.

Ravindra Puranik, Oil and Gas Analyst at GlobalData, commented: “Heavy machinery deployed at oil and gas facilities

is expected to operate reliably and efficiently for years to come. To guarantee the longevity of the equipment,

maintenance work is necessary to keep the equipment Being in top working condition and timely maintenance also helps

prevent costly repair works and unplanned production interruptions.”

Unplanned downtime due to equipment failure can result in significant cost to oil and gas companies. The consequent

effects of equipment failure can be far-reaching, not just financial losses. For example, the May 2020 Norilsk diesel spill

in Russia resulted in the pollution of 17,500 tons of diesel in nearby rivers. Events like these highlight the need for

predictive maintenance in the energy sector.

"An effective predictive maintenance strategy for oil and gas equipment relies on regular data collection. This data is used

to determine the state of disrepair, which is then used to assess the appropriate corrective action needed," Puranikc said.

Although predictive maintenance has been around as a concept for more than 20 years, advances in technology have

given it a shot in the arm for its use in the oil and gas industry.

Puranik added: “The emergence and rapid growth of innovative technologies such as the Internet of Things, artificial

intelligence, augmented and virtual reality, big data and cloud computing have shaped the maintenance strategies of

the oil and gas industry in the near term.”

Disclaimer

Articles and pictures are from the Internet. In order to disseminate more oil and gas industry information, the content reprinted

by Petroleum and Equipment shall remain neutral to the authenticity, opinions and judgments stated in the article, and shall not

provide any express or clear indication of the accuracy, reliability or completeness of the content. Implied warranty. Readers are

requested to use it as a reference only and to take full responsibility for it. If you have any questions about the content of the

work, copyright and other issues, please contact us in time.